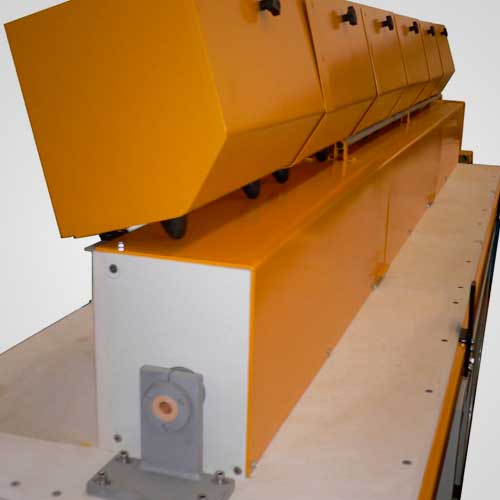

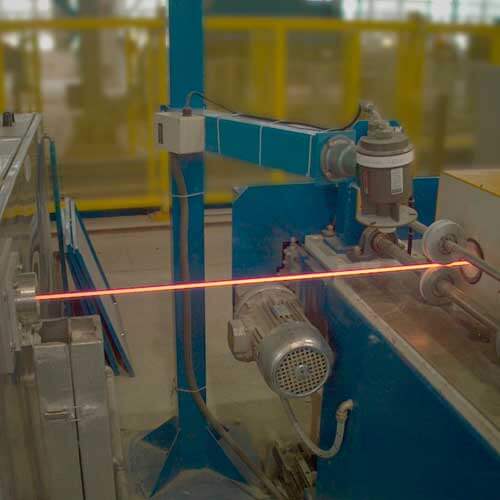

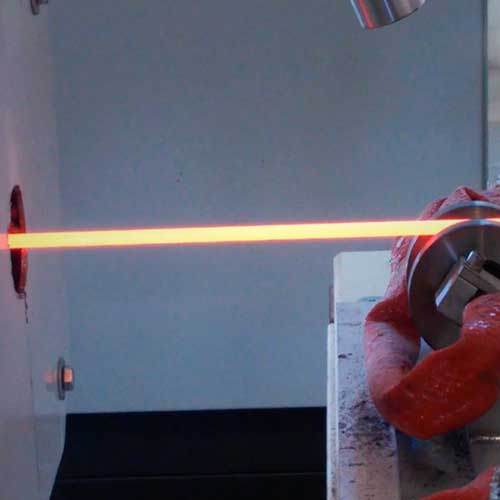

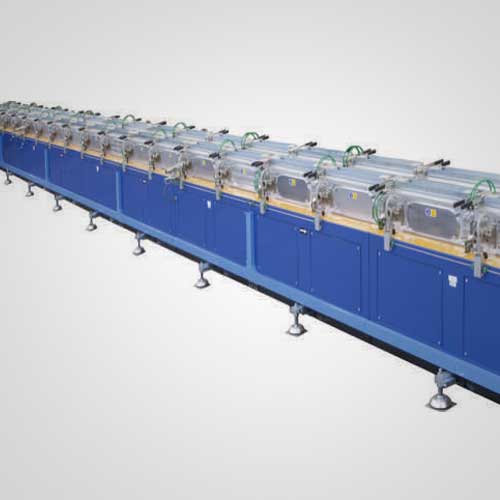

Stabilisation heat treatment

for steel wires and strands

Stabilisation induction heat treatment is applied to reduce slackening in steel wires, braids and strands for prestressed reinforced concrete used in building large-sized structures and prefabricated elements as bridges, tunnels, viaducts, dams, geotechnical rods and railway sleepers.