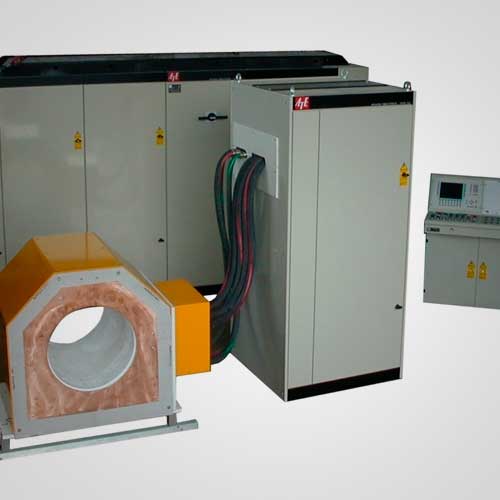

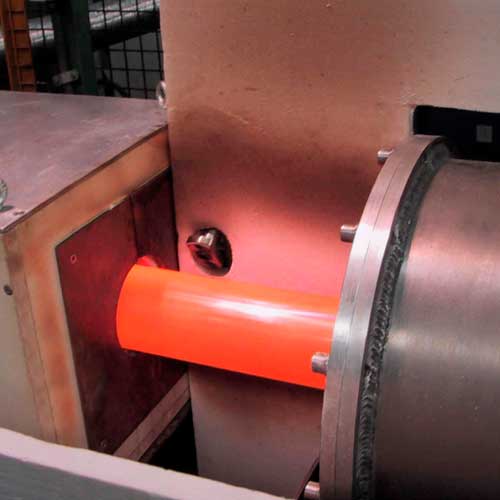

Induction heating of pipes for drying, desiccation, painting, plastic surface coating

Liquids, paints, lubricants, polymeric coatings can be heated in a very effective way if they are or come into contact with induction-heated metal materials.

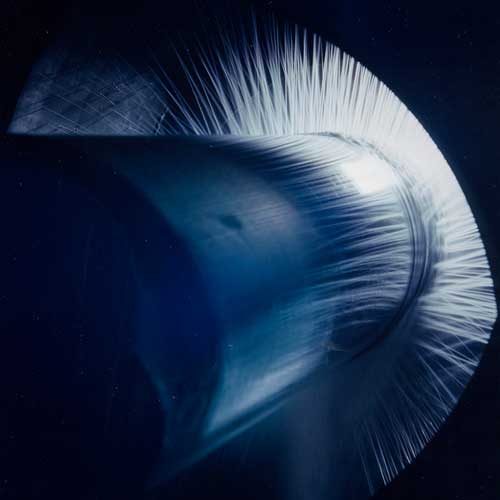

With induction heating, the direct heating by “skin effect” of a surface layer of parallel multi-wires is carried out, making the processes of drying, desiccation of lubricants, painting, galvanising and coating with polymers much quicker, repeatable with a limited use of space and energy compared to hot air or irradiation systems.