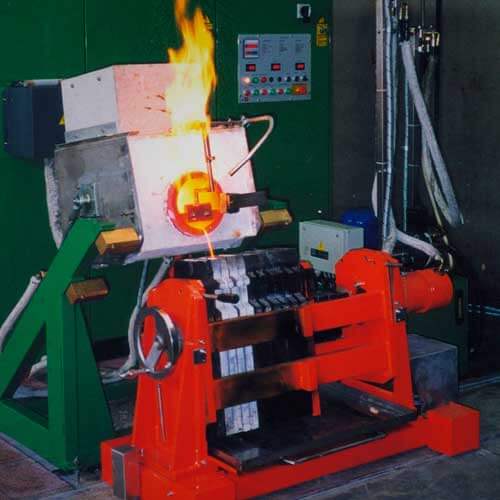

Induction heating is widely used for melting precious metals (gold, silver, copper, palladium, platinum) and their alloys and in the melting of other pure non-ferrous metals or alloys (copper, aluminium, brass, bronze, etc.)

Induction systems are used in various fields to produce various types of machining in the industry of the production of precious and non-ferrous metals.

In addition to the melting of small or large quantities of pure precious metals or alloys, induction heating systems are also used to produce semi-finished metals (bars, pipes, profiles) through continuous casting, in the production of ingots through bracket casting, in refining metals and in making objects through lost-wax casting.

In induction melting systems, heat is generated by eddy currents induced inside the crucibles used for casting or directly into the material to be melted in the case of using insulating crucibles, transparent to the electro-magnetic field.

Conductive crucibles are generally made of graphite, silicon carbide, graphite mixture, while insulating crucibles are made of ceramic materials.

Induction melting provides several advantages compared to traditional melting methods. Firstly, induction heating is a technology that respects the working environment, in fact, it emits no hot and harmful emissions into the atmosphere.

Furthermore, as heat is generated by eddy currents induced inside crucibles used for melting or directly into the material being heated, the heating times are much faster than traditional heating technologies with gas burners or through electric resistors.

The currents induced into the material also remix the elements present in the bath of the melting alloy allowing the creation of finished products with even dispersion of the elements constituting the alloy.