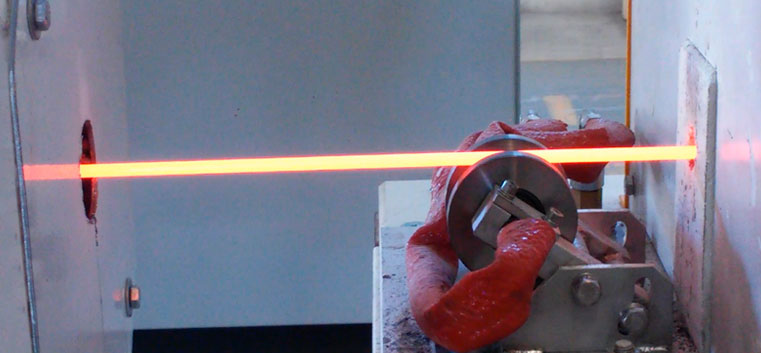

Heat treatment systems for wires and braids.

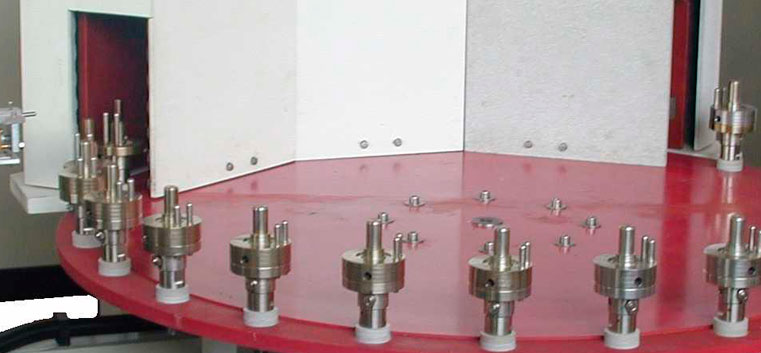

PTo carry out inline (during production) actions of induction heating on wires and braids, ATE produces systems that heat the workpieces to be treated before hot galvanizing for example, or for drying after the bath, for polymerising paints or for brass coating wires.

These systems are designed for:

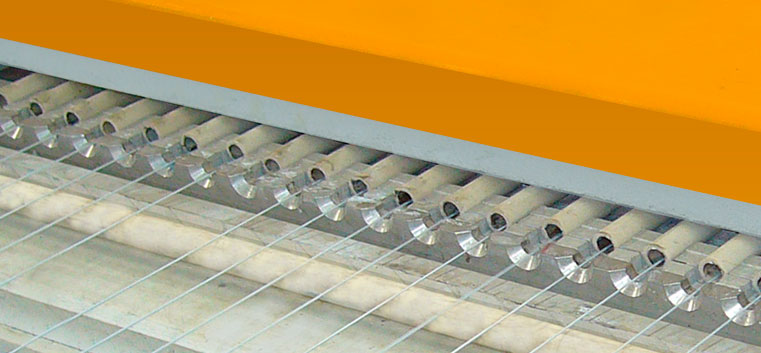

- Stabilization induction heat treatment of steel wires, braids and strands,

- Induction heating for drying, desiccation and surface plastic coating of wires, strands and profile strips,

- Induction heating for subsequent plastic coating of steel strands and cables,

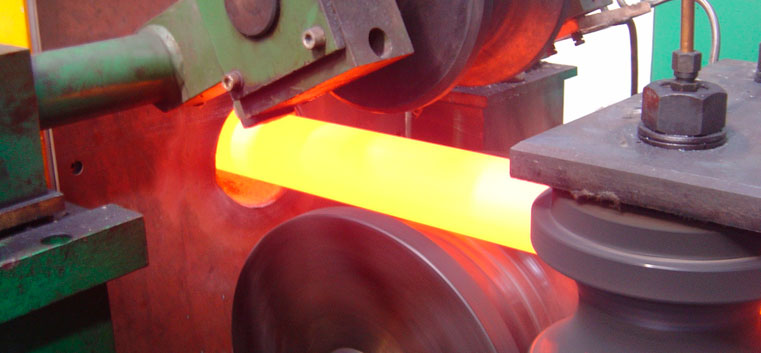

- Annealing heat treatment to relieve stress in steel wires, strips and profiles,

- Induction heating for tempering surface martensite on steel wires,

- Hardening and tempering of steel wires, strips, profiles and steel wires for springs.